THE MOST POWERFUL MICRO-CALORIMETER - CAL L92

THE MOST POWERFUL MICRO-CALORIMETER

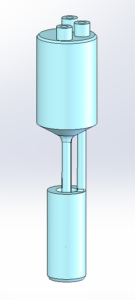

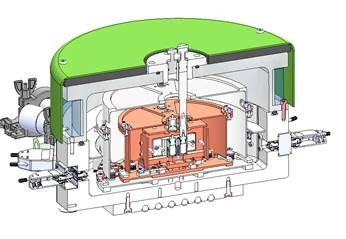

The Ultimate micro calorimeter CAL L92 is a differential temperature scanning micro calorimeter offering unrivalled sensitivity, enabling the study of all types of materials, especially the most dilute solutions. It operates in the same way as a conventional micro-calorimeter.

Its unique and innovative design, enables to achieve measurements with a sensitivity never reached before by a micro-calorimeter with extractable vessels/test crucibles.

Its performance is based essentially on 2 cutting-edge technologies:

1- An ultra-sensitive sensor based on the most sensitive Peltier element technology on the market.

2- A measurement environment consisting of a sealed enclosure ensuring unrivalled thermal stability.

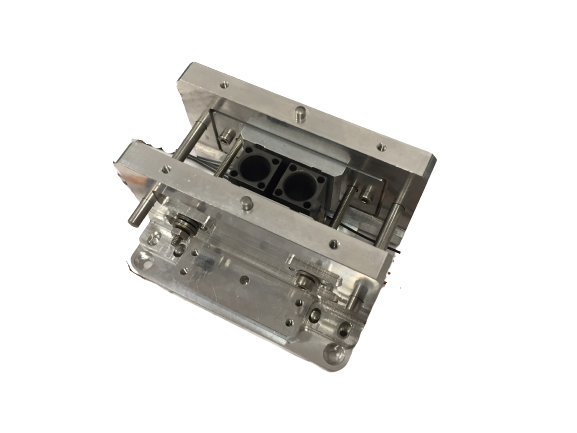

With its extractable cells, the volume of sample used is reduced to the strictly necessary (up to 750 µl).

This environment has been designed to be scalable, enabling custom developments for/or by users.

These cells can be used to study solids and liquids. They are ideal for precise measurements (better than 3%) of mass heat capacities, and are reusable. They can also be used to study transitions (melting/crystallization) and liquid-solid or liquid-liquid phase diagrams.

Useful volume: 850 µl

Closed system (silicone O-ring): mass measurement

Pressure: a few bars

They are identical to batch cells, with a pressurization tube to control pressure using the appropriate pressurization system.

Useful volume: Up to 330 µl (pressure dependent)

Closed system (silicone O-ring): mass measurement

Pressure: up to 1000 bars

These cells have been specifically developed for measuring the heat capacity of pressurized liquids. Their unique design makes them easy to fill and clean.

Measurements are carried out in constant volume, and the cells are installed in the instrument for the entire measurement campaign.

They don’t need to be removed to change the liquid being measured, which means that Cp volumetric measurements are more accurate than 1%.

These cells can be used to observe very weak liquid-liquid transitions such as “demixing” or “degassing”.

They can be used at atmospheric pressure or under a few bars, and have been tested up to 100 bars. With the right equipment, these cells can also be filled under pressure. They can therefore be used to analyze solutions loaded with pressurized gases.

Useful volume: 750 µL

Open system: volume measurement

Pressure: 100 bar

These cells are ideal for rapidly determining reaction enthalpies involving at least 1 liquid. Very similar to “batch” cells, these cells can be used to inject a liquid reagent onto a solid or other liquid at room temperature, using a syringe. They can also be used at other temperatures, but depending on the enthalpy of reaction, they may require a thermostatically-controlled injection system to avoid a Cp effect during injection. Measurements under pressure are possible, but require a specific system.

Useful volume: 700 µL

Closed system: mass measurement

These cells enable enthalpy of reaction measurements to be carried out while limiting the Cp effect of injection. A liquid is charged into the upper compartment and injected into the lower compartment (solid or liquid).

Useful volumes: 150+250 µL

Closed system: mass measurement

Pressure: a few bars

These cells enable direct measurement of enthalpies of reaction or enthalpies of mixing of a liquid and a fluid (liquid or gas) under pressure. These cells require a precise injection system to determine mixing ratios. Energy measurement is continuous and does not require peak integration.

Continuous flow system

Pressure: 100 bar

These cells measure the enthalpy of mixing of 2 fluids in continuous flow (heat of chemical reaction, heat of gas dissolution or enthalpy of excess of a liquid mixture). The measurement is performed dynamically. An internal tubing system is used to equilibrate the fluids to the study temperature, then mixing takes place within the measuring system, before being discharged outside the calorimeter. The heat measured is directly proportional to the flow rates and heats measured.

Continuous flow system

Isothermal measurements

Pressures: up to 100 bar (higher pressures on request)

Flow rates: up to 1mL/min

SPECIFICATIONS

-

Temperature range :

-60 °C up to +170 °C

-

Scanning rate :

0,001 up to 5°C/min

-

Temperature precision regulation :

100 µ°C

-

Measurement time

30 to 60 minutes typically

-

Sample volume :

up to 850 µL depending on vessel type. Measurement chamber : diam 9mm – H 24,5mm

-

Sensor type

Peltier elements

-

Sensitivity

250 µV/mW

-

Uniques standard features

Direct T sample measurement Joule effect calibration

-

Measurement range

+/- 150 mW

-

RMS Noise

0.05 µW

-

Dimensions

L*p*h =700*650*500 mm

DOCUMENTS TO DOWNLOAD

The most powerful MICRO-CALORIMETER on the market.

Phase transitions in PTFE close to ambient temperature